| Brand Name: | GT SONIC |

| Model Number: | GT SONIC-ST105A/B |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | Gift box & master carton |

| Payment Terms: | T/T, Western Union, MoneyGram |

105l 28k Ultrasonic Cleaning Machine For Mold Parts Bearing Parts Electrician Parts Auto Parts Aircraft Parts Ship Parts

Ultrasonic cleaning machines use high-frequency sound waves to create microscopic bubbles in a cleaning solution. These bubbles implode upon contact with the mold parts, creating a scrubbing action that removes dirt, grime, and other contaminants from the surface of the parts. This process is highly effective at cleaning intricate and hard-to-reach areas that are not accessible with traditional cleaning methods. Additionally, ultrasonic cleaning is a gentle process that does not damage the mold parts, making it an ideal solution for delicate components.

Specifications:

|

Model |

Tank Size |

Unit Size |

Volume |

Ultrasonic |

Ultrasonic |

Heating |

Timer |

Heating |

|

L x W x H (mm) |

L x W x H (mm) |

(L) |

(W) |

(KHz) |

(W) |

(MIN) |

(℃) |

|

|

GT SONIC-ST105A/B |

600*500*350 |

745*645*665 |

105 |

1500 |

40/28 |

4000 |

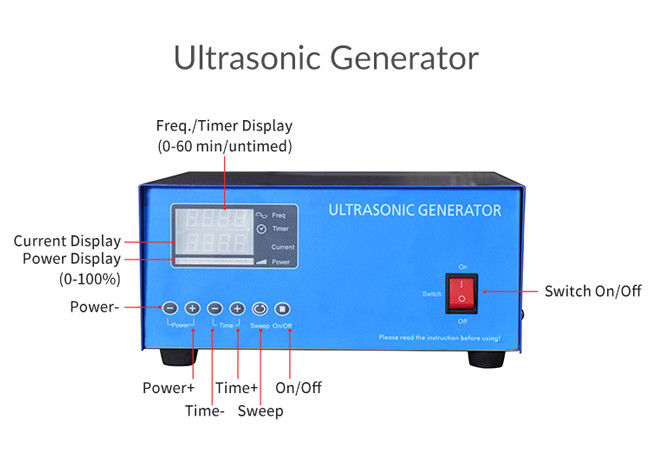

0-60//untimed |

30-110 |

Features:

4000W heater to provide even more efficient cleaning of dirt, paint, and the most stubborn stains.

105 liters Basin offers outstanding professional service, ideal for all your industrial needs.

Helpful Basket holds your objects to prevent damage to them and the inside of the machine, while also easily draining any cleaning solution after operation.

Low-Noise Operation The stainless steel lid effectively suppresses noise during operation and ensures stable and splash-free performance.

Applications:

Engineering: Cleaning of parts, pipes, wires, etc. before finishing, machining parts and components to the preservation, processing of parts after reopening, welding, grinding, polishing, cleaning strainers in the fuel and hydraulic systems, and deburring parts.

Instrumentation: Washing and polishing of optics, precision mechanics components, integrated circuits, and printed circuit boards.

How to select an ultrasonic cleaner for mold parts cleaning?

Size: Choose a machine that can accommodate the size of your largest mold part.

Frequency: The frequency of the ultrasonic waves determines the size of the bubbles and the intensity of the cleaning action. Higher frequencies are better for smaller parts, while lower frequencies are better for larger parts.

Power: The power of the ultrasonic waves determines the strength of the cleaning action. Higher power is better for tougher contaminants, while lower power is better for delicate parts.

Tank Material: The material of the tank should be compatible with the cleaning solution and the mold parts being cleaned.

Temperature Control: Some cleaning solutions require specific temperature ranges for optimal cleaning performance, so choose a machine with temperature control if necessary.

1. How often should I change the cleaning solution in my ultrasonic cleaner?

A: The frequency of solution changes will depend on the type of items being cleaned and the level of contamination. As a general rule, it is recommended to change the solution after every cleaning cycle or when it becomes visibly dirty or contaminated.

2. How does an ultrasonic cleaner work?

A: Ultrasonic cleaners use high-frequency sound waves to generate cavitation bubbles in a cleaning solution. These bubbles implode near the surface of the item being cleaned, producing a scrubbing action that removes dirt, grease, and other contaminants.

3. Can ultrasonic cleaners remove rust?

A: Ultrasonic cleaners can be effective at removing rust from metal surfaces, but they may require a specialized cleaning solution and a longer cleaning cycle.

4. What kind of cleaning solution should I use in an ultrasonic cleaner?

A: The type of cleaning solution used will depend on the item being cleaned and the level of cleaning required. There are many different types of solutions available, including water-based solutions, solvent-based solutions, and specialized solutions for specific cleaning applications.

| Brand Name: | GT SONIC |

| Model Number: | GT SONIC-ST105A/B |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | Gift box & master carton |

| Payment Terms: | T/T, Western Union, MoneyGram |

105l 28k Ultrasonic Cleaning Machine For Mold Parts Bearing Parts Electrician Parts Auto Parts Aircraft Parts Ship Parts

Ultrasonic cleaning machines use high-frequency sound waves to create microscopic bubbles in a cleaning solution. These bubbles implode upon contact with the mold parts, creating a scrubbing action that removes dirt, grime, and other contaminants from the surface of the parts. This process is highly effective at cleaning intricate and hard-to-reach areas that are not accessible with traditional cleaning methods. Additionally, ultrasonic cleaning is a gentle process that does not damage the mold parts, making it an ideal solution for delicate components.

Specifications:

|

Model |

Tank Size |

Unit Size |

Volume |

Ultrasonic |

Ultrasonic |

Heating |

Timer |

Heating |

|

L x W x H (mm) |

L x W x H (mm) |

(L) |

(W) |

(KHz) |

(W) |

(MIN) |

(℃) |

|

|

GT SONIC-ST105A/B |

600*500*350 |

745*645*665 |

105 |

1500 |

40/28 |

4000 |

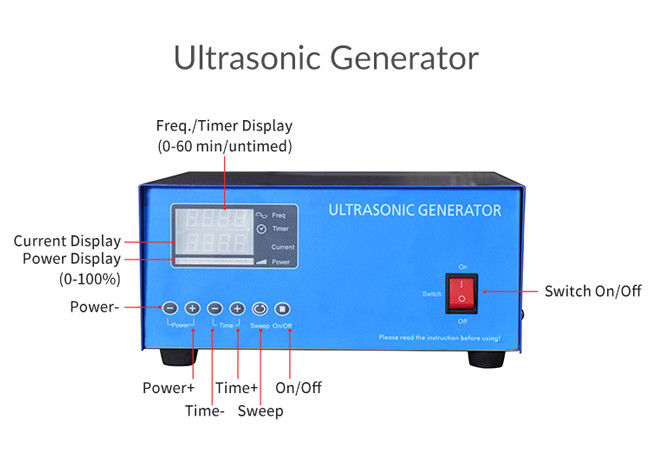

0-60//untimed |

30-110 |

Features:

4000W heater to provide even more efficient cleaning of dirt, paint, and the most stubborn stains.

105 liters Basin offers outstanding professional service, ideal for all your industrial needs.

Helpful Basket holds your objects to prevent damage to them and the inside of the machine, while also easily draining any cleaning solution after operation.

Low-Noise Operation The stainless steel lid effectively suppresses noise during operation and ensures stable and splash-free performance.

Applications:

Engineering: Cleaning of parts, pipes, wires, etc. before finishing, machining parts and components to the preservation, processing of parts after reopening, welding, grinding, polishing, cleaning strainers in the fuel and hydraulic systems, and deburring parts.

Instrumentation: Washing and polishing of optics, precision mechanics components, integrated circuits, and printed circuit boards.

How to select an ultrasonic cleaner for mold parts cleaning?

Size: Choose a machine that can accommodate the size of your largest mold part.

Frequency: The frequency of the ultrasonic waves determines the size of the bubbles and the intensity of the cleaning action. Higher frequencies are better for smaller parts, while lower frequencies are better for larger parts.

Power: The power of the ultrasonic waves determines the strength of the cleaning action. Higher power is better for tougher contaminants, while lower power is better for delicate parts.

Tank Material: The material of the tank should be compatible with the cleaning solution and the mold parts being cleaned.

Temperature Control: Some cleaning solutions require specific temperature ranges for optimal cleaning performance, so choose a machine with temperature control if necessary.

1. How often should I change the cleaning solution in my ultrasonic cleaner?

A: The frequency of solution changes will depend on the type of items being cleaned and the level of contamination. As a general rule, it is recommended to change the solution after every cleaning cycle or when it becomes visibly dirty or contaminated.

2. How does an ultrasonic cleaner work?

A: Ultrasonic cleaners use high-frequency sound waves to generate cavitation bubbles in a cleaning solution. These bubbles implode near the surface of the item being cleaned, producing a scrubbing action that removes dirt, grease, and other contaminants.

3. Can ultrasonic cleaners remove rust?

A: Ultrasonic cleaners can be effective at removing rust from metal surfaces, but they may require a specialized cleaning solution and a longer cleaning cycle.

4. What kind of cleaning solution should I use in an ultrasonic cleaner?

A: The type of cleaning solution used will depend on the item being cleaned and the level of cleaning required. There are many different types of solutions available, including water-based solutions, solvent-based solutions, and specialized solutions for specific cleaning applications.