| Brand Name: | GT SONIC |

| Model Number: | GT-D20 |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | Gift box & master carton |

| Payment Terms: | T/T, Western Union, MoneyGram |

What is the principle of an ultrasonic cleaner?

Mainly through the transducer, the sound energy of the power ultrasonic frequency source is converted into mechanical vibration, and the ultrasonic wave is radiated to the cleaning liquid in the tank through the cleaning tank wall. Due to the ultrasonic radiation, the microbubbles in the liquid in the tank can maintain vibration under the action of sound waves. Destroy the adsorption of the dirt and the surface of the cleaning part, cause the fatigue damage of the dirt layer and be dismissed, and the vibration of the gas bubble scrubs the solid surface.

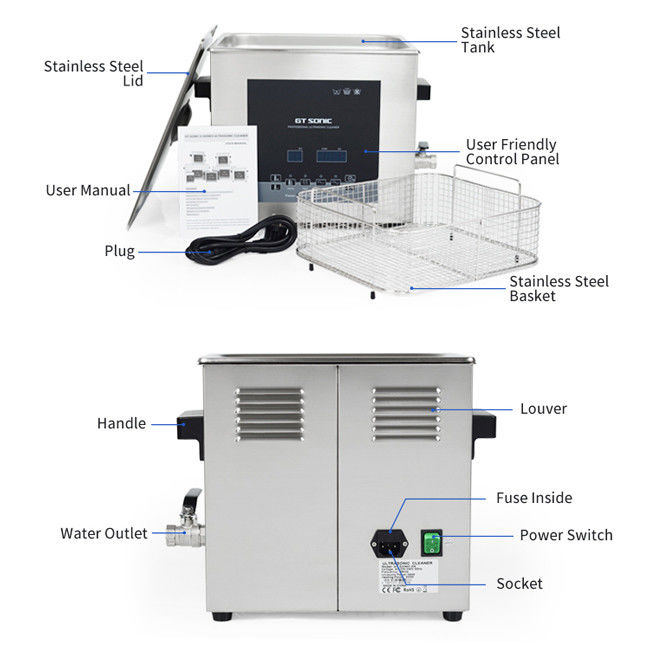

Specifications:

| Model | Tank Size | Unit Size | Volume | Ultrasonic Power |

Ultrasonic Frequency |

Heating Power |

Timer | Heating Temperature |

| L x W x H (mm) | L x W x H (mm) | (L) | (W) | (KHz) | (W) | (MIN) | (℃) | |

| D20 | 500*300*150 | 550*330*310 | 20 | 400 | 40 | 500 | 1-99 | 0-80 |

Features:

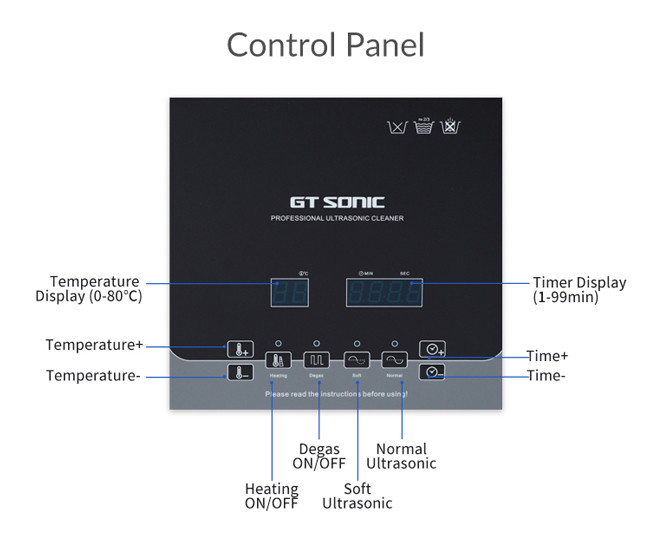

1. Normal and soft power control is widely used for different items

2. Degas function for improving the cleaning effect

3. 40KHz ultrasonic frequency is suitable for more items

4. 0 to 80℃ heating adjustable temperature

5. Memory function, easier operation every time

Applications:

More Applications of GT SONIC Ultrasonic Cleaner:

Our other ultrasonic cleaners are used to clean many different types of objects, including industrial parts, jewelry, scientific samples, lenses, and other optical parts, watches, dental and surgical instruments, tools, coins, fountain pens, golf clubs, fishing reels, window blinds, firearm components, car fuel injectors, musical instruments, gramophone records, industrial machined parts, and electronic equipment, optical lenses, etc. They are used in many jewelry workshops, watchmakers' establishments, electronic repair workshops, and scientific labs.

1. What are your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost-effective for you.

2. How do you control the quality?

Three tests on production lines, IQC department to check the quality again.

100% test for all products before shipment.

3. What is the lead time after the customer place order?

Usually, our lead time is 5-7 days after we confirm payment.

4. How to choose suitable equipment?

Tell us your requirements, and our professional sales will introduce you to the most suitable model.

| Brand Name: | GT SONIC |

| Model Number: | GT-D20 |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | Gift box & master carton |

| Payment Terms: | T/T, Western Union, MoneyGram |

What is the principle of an ultrasonic cleaner?

Mainly through the transducer, the sound energy of the power ultrasonic frequency source is converted into mechanical vibration, and the ultrasonic wave is radiated to the cleaning liquid in the tank through the cleaning tank wall. Due to the ultrasonic radiation, the microbubbles in the liquid in the tank can maintain vibration under the action of sound waves. Destroy the adsorption of the dirt and the surface of the cleaning part, cause the fatigue damage of the dirt layer and be dismissed, and the vibration of the gas bubble scrubs the solid surface.

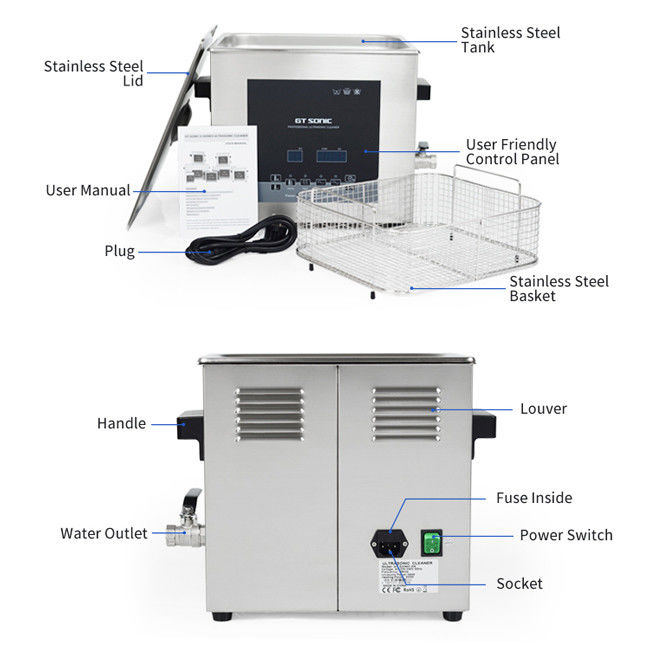

Specifications:

| Model | Tank Size | Unit Size | Volume | Ultrasonic Power |

Ultrasonic Frequency |

Heating Power |

Timer | Heating Temperature |

| L x W x H (mm) | L x W x H (mm) | (L) | (W) | (KHz) | (W) | (MIN) | (℃) | |

| D20 | 500*300*150 | 550*330*310 | 20 | 400 | 40 | 500 | 1-99 | 0-80 |

Features:

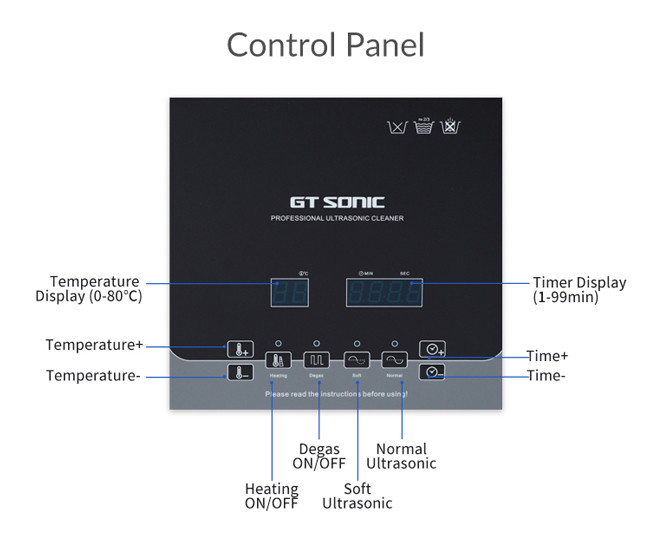

1. Normal and soft power control is widely used for different items

2. Degas function for improving the cleaning effect

3. 40KHz ultrasonic frequency is suitable for more items

4. 0 to 80℃ heating adjustable temperature

5. Memory function, easier operation every time

Applications:

More Applications of GT SONIC Ultrasonic Cleaner:

Our other ultrasonic cleaners are used to clean many different types of objects, including industrial parts, jewelry, scientific samples, lenses, and other optical parts, watches, dental and surgical instruments, tools, coins, fountain pens, golf clubs, fishing reels, window blinds, firearm components, car fuel injectors, musical instruments, gramophone records, industrial machined parts, and electronic equipment, optical lenses, etc. They are used in many jewelry workshops, watchmakers' establishments, electronic repair workshops, and scientific labs.

1. What are your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost-effective for you.

2. How do you control the quality?

Three tests on production lines, IQC department to check the quality again.

100% test for all products before shipment.

3. What is the lead time after the customer place order?

Usually, our lead time is 5-7 days after we confirm payment.

4. How to choose suitable equipment?

Tell us your requirements, and our professional sales will introduce you to the most suitable model.