|

| Brand Name: | GT SONIC |

| Model Number: | GT SONIC-D3 |

| MOQ: | 1pc |

| Price: | Negotiable |

| Packaging Details: | Packing material: pearl wool and corrugated carton. |

| Payment Terms: | L/C, T/T, Western Union, PayPal, Credit card |

GT SONIC D series Ultrasonic cleaners are the improved version of the VGT-QTD series with dual power and degas function.

The 40kHz frequency makes it suitable for general cleaning applications.D series comprises 7 machine sizes from 2 liters to 27 liters.

There are 7 sizes for different Ultrasonic cleaning purposes.

Features

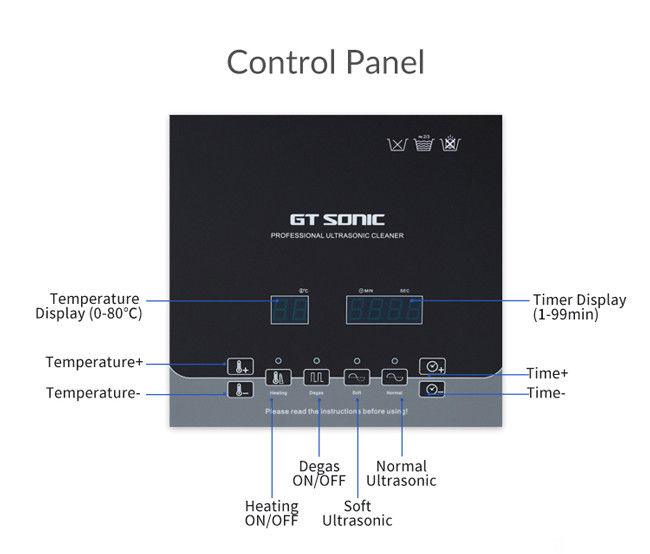

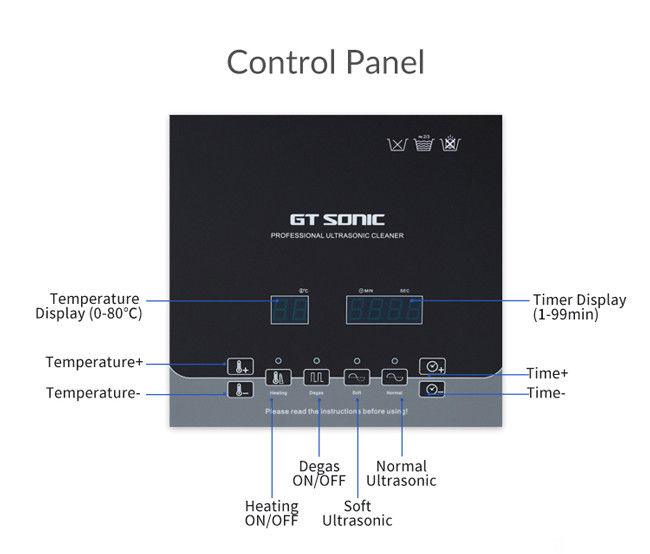

1. Normal and soft power control to resolve the cleaning blind spot.:

2. Degas function to improve the cleaning effect.

3. Time Setting:1-99minutes adjustable.

4. Heating: 0-80℃ temperature adjustable.

5. User-friendly and clear panel

6. Memory function.

7. LED display for temperature and timer

8. High-performance transducer.

9. Patent products.

Specification of GT SONIC-D3:

|

Model |

GT SONIC-D3 |

|

Voltage |

AC100~120V, 60Hz; AC220~240V, 50Hz |

|

Frequency |

40KHz |

|

Power |

100W |

|

Tank capacity |

3L |

|

Tank size(mm) |

240×140×100 (L×W×H) |

|

Overall size(mm) |

270×170×240 (L×W×H) |

|

Unit weight |

3.8KG |

|

Lid |

Have |

|

Heating |

Have |

|

Drainage |

None |

|

Cleaning basket |

Have |

|

Model |

Tank size |

Unit size |

Volume |

Ultrasonic power |

Ultrasonic frequency |

Heating power |

Timer |

Heating temperature |

|

L×W×H(mm) |

L×W×H(mm) |

(L) |

Normal (W) |

(kHz) |

(W) |

(MIN) |

(℃) |

|

|

GT SONIC-D2 |

150*140*100 |

190*170*220 |

2 |

50 |

40

|

100 |

1-99 |

0-80 |

|

GT SONIC-D3 |

240*140*100 |

270*170*240 |

3 |

100 |

100 |

1-99 |

0-80 |

|

|

GT SONIC-D6 |

300*155*150 |

330*180*310 |

6 |

150 |

300 |

1-99 |

0-80 |

|

|

GT SONIC-D9 |

300*240*150 |

330*270*310 |

9 |

200 |

300 |

1-99 |

0-80 |

|

|

GT SONIC-D13 |

330*300*150 |

360*330*310 |

13 |

300 |

400 |

1-99 |

0-80 |

|

|

GT SONIC-D20 |

500*300*150 |

550*330*310 |

20 |

400 |

500 |

1-99 |

0-80 |

|

|

GT SONIC-D27 |

500×300×200 |

550×330×360 |

27 |

500 |

500 |

1-99 |

0-80 |

Ultrasonic cleaning:

The Ultrasonic cleaning process provides high-quality cleaning and exceeds, by the ease of use and end result, conventional cleaning methods. The tiny microscopic bubbles generated by the transducers provide cleaning of very difficult, irregular, and complex parts. Even inaccessible areas can be cleaned without any trace of physical cleaning (scratches, etc.). The Ultrasonic cleaner is widely applied to different fields such as dental instruments, lab instruments, hospitals, instruments, blinds, PC boards, hardware, the chemical industry, circuit board, carburetor, printer heads, etc.

Application of benchtop Ultrasonic cleaners:

|

Industry |

Items to be cleaned |

|

Molds |

Plastic tool models --For cleaning. |

|

Electronics |

Relay—remove metal filings and impurities, Potentiometer-- impurities and oil stain on moving contact, Vacuum tube parts-- Dirt and impurity on the polar plate of the electron gun, Semiconductor element--Dir on the surface of the silicon wafer and crystal wafer, Capacitor--Dirt on pins of the capacitor, Printed circuit board--Ink and oxide left during the processing of printed circuit board, Magnetic head--Dirt on the surface of the magnetic head. |

|

Mechanical |

Bearing, gear--Metal filings and impurities left during the processing of internal and external sheath of bearing, Spring--cleaning before spring turns black, Vernier caliper, measuring tool--Metal filings and oil stain left during the processing of parts, Oil choke, oil pump--Metal filings and dirt left during the process of the inner hole of the oil choke and oil pump, Screw rod, air valve, pneumatic elements--Iron filings, cutting oil and abrasive left while processing. |

|

Automotive, motorcycle, aircraft |

To remove oil, grease, preservative, the plastic residue left during mechanical cutting, grinding abrasive, glass fiber, dust, graphite, and tar from Automotive air valve, glow plug, gasification plug, fuel pump, piston ring, battery terminal, machine control hand-wheel, motorcycle air-valve, etc. |

|

Armurerie |

weapons cleaning, such as guns, rifles, bullets, handcuffs, etc. --For cleaning and lubrication. |

|

Printing industry |

Rotative machine, metal plate, Printer ink head, printer cartridges -- To clean ink, oil, and dye on the surface of the printing machine & parts. |

|

Repair industry |

Musical instrument repair shops, vehicle maintenance shops, motorcycle repair shops, mobile phones & interphone repair shops, gun repair shops, etc. --To clean dirt, impurity, and oils from the surface of tools and spare parts. |

|

Watch & clock |

Gear wheel, pin, screw, movement of watches for watch manufacture, |

Product details:

|

| Brand Name: | GT SONIC |

| Model Number: | GT SONIC-D3 |

| MOQ: | 1pc |

| Price: | Negotiable |

| Packaging Details: | Packing material: pearl wool and corrugated carton. |

| Payment Terms: | L/C, T/T, Western Union, PayPal, Credit card |

GT SONIC D series Ultrasonic cleaners are the improved version of the VGT-QTD series with dual power and degas function.

The 40kHz frequency makes it suitable for general cleaning applications.D series comprises 7 machine sizes from 2 liters to 27 liters.

There are 7 sizes for different Ultrasonic cleaning purposes.

Features

1. Normal and soft power control to resolve the cleaning blind spot.:

2. Degas function to improve the cleaning effect.

3. Time Setting:1-99minutes adjustable.

4. Heating: 0-80℃ temperature adjustable.

5. User-friendly and clear panel

6. Memory function.

7. LED display for temperature and timer

8. High-performance transducer.

9. Patent products.

Specification of GT SONIC-D3:

|

Model |

GT SONIC-D3 |

|

Voltage |

AC100~120V, 60Hz; AC220~240V, 50Hz |

|

Frequency |

40KHz |

|

Power |

100W |

|

Tank capacity |

3L |

|

Tank size(mm) |

240×140×100 (L×W×H) |

|

Overall size(mm) |

270×170×240 (L×W×H) |

|

Unit weight |

3.8KG |

|

Lid |

Have |

|

Heating |

Have |

|

Drainage |

None |

|

Cleaning basket |

Have |

|

Model |

Tank size |

Unit size |

Volume |

Ultrasonic power |

Ultrasonic frequency |

Heating power |

Timer |

Heating temperature |

|

L×W×H(mm) |

L×W×H(mm) |

(L) |

Normal (W) |

(kHz) |

(W) |

(MIN) |

(℃) |

|

|

GT SONIC-D2 |

150*140*100 |

190*170*220 |

2 |

50 |

40

|

100 |

1-99 |

0-80 |

|

GT SONIC-D3 |

240*140*100 |

270*170*240 |

3 |

100 |

100 |

1-99 |

0-80 |

|

|

GT SONIC-D6 |

300*155*150 |

330*180*310 |

6 |

150 |

300 |

1-99 |

0-80 |

|

|

GT SONIC-D9 |

300*240*150 |

330*270*310 |

9 |

200 |

300 |

1-99 |

0-80 |

|

|

GT SONIC-D13 |

330*300*150 |

360*330*310 |

13 |

300 |

400 |

1-99 |

0-80 |

|

|

GT SONIC-D20 |

500*300*150 |

550*330*310 |

20 |

400 |

500 |

1-99 |

0-80 |

|

|

GT SONIC-D27 |

500×300×200 |

550×330×360 |

27 |

500 |

500 |

1-99 |

0-80 |

Ultrasonic cleaning:

The Ultrasonic cleaning process provides high-quality cleaning and exceeds, by the ease of use and end result, conventional cleaning methods. The tiny microscopic bubbles generated by the transducers provide cleaning of very difficult, irregular, and complex parts. Even inaccessible areas can be cleaned without any trace of physical cleaning (scratches, etc.). The Ultrasonic cleaner is widely applied to different fields such as dental instruments, lab instruments, hospitals, instruments, blinds, PC boards, hardware, the chemical industry, circuit board, carburetor, printer heads, etc.

Application of benchtop Ultrasonic cleaners:

|

Industry |

Items to be cleaned |

|

Molds |

Plastic tool models --For cleaning. |

|

Electronics |

Relay—remove metal filings and impurities, Potentiometer-- impurities and oil stain on moving contact, Vacuum tube parts-- Dirt and impurity on the polar plate of the electron gun, Semiconductor element--Dir on the surface of the silicon wafer and crystal wafer, Capacitor--Dirt on pins of the capacitor, Printed circuit board--Ink and oxide left during the processing of printed circuit board, Magnetic head--Dirt on the surface of the magnetic head. |

|

Mechanical |

Bearing, gear--Metal filings and impurities left during the processing of internal and external sheath of bearing, Spring--cleaning before spring turns black, Vernier caliper, measuring tool--Metal filings and oil stain left during the processing of parts, Oil choke, oil pump--Metal filings and dirt left during the process of the inner hole of the oil choke and oil pump, Screw rod, air valve, pneumatic elements--Iron filings, cutting oil and abrasive left while processing. |

|

Automotive, motorcycle, aircraft |

To remove oil, grease, preservative, the plastic residue left during mechanical cutting, grinding abrasive, glass fiber, dust, graphite, and tar from Automotive air valve, glow plug, gasification plug, fuel pump, piston ring, battery terminal, machine control hand-wheel, motorcycle air-valve, etc. |

|

Armurerie |

weapons cleaning, such as guns, rifles, bullets, handcuffs, etc. --For cleaning and lubrication. |

|

Printing industry |

Rotative machine, metal plate, Printer ink head, printer cartridges -- To clean ink, oil, and dye on the surface of the printing machine & parts. |

|

Repair industry |

Musical instrument repair shops, vehicle maintenance shops, motorcycle repair shops, mobile phones & interphone repair shops, gun repair shops, etc. --To clean dirt, impurity, and oils from the surface of tools and spare parts. |

|

Watch & clock |

Gear wheel, pin, screw, movement of watches for watch manufacture, |

Product details: