|

| Brand Name: | GT SONIC |

| Model Number: | VGT-1036S |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | standard packing : wooden case |

| Payment Terms: | L/C, T/T |

Ultrasonic Cleaning Machine Features:

1. Whole machine made of SUS304 stainless steel, 2mm thickness tank for acid-proof, anti-corrosive.

2. Industrial grade Ultrasonic transducer, moisture-proofed PCB.

3. Advanced generator, sweep frequency, high quality, better effect.

4. Ultrasonic power can be adjusted from 0-100%.

5. Temperature can be set from 30-110°C.

6. Industrial grade for 24 hours of continuous working.

7. Ultrasonic frequency: 28kHz or 40kHz.

8. Fully portable, 36L and above volume machines are with wheels, locking wheels for stability.

9. With free lid and stainless steel SUS304 basket.

Specifications of Ultrasonic Cleaning Equipment:

|

Model

|

|

Volume

|

Ultrasonic Power

|

Ultrasonic Frequency

|

Heating power

|

Heating temperature

|

|

(L×W×H)mm

|

(L)

|

(W)

|

(kHz)

|

(W)

|

(℃)

|

|

|

VGT-2200QT |

400×360×450

|

13

|

360

|

40

|

500

|

0-80

|

|

VGT-2300

|

570×360×450

|

36

|

720

|

28/40

|

800

|

30-110

|

|

VGT-1012S

|

530×430×600

|

40

|

720

|

28/40

|

2000

|

30-110

|

|

VGT-1018S

|

630×480×650

|

65

|

1080

|

28/40

|

3000

|

30-110

|

|

VGT-1024S

|

730×530×700

|

96

|

1440

|

28/40

|

4000

|

30-110

|

|

VGT-1030S

|

790×590×700

|

117

|

1800

|

28/40

|

4000

|

30-110

|

|

VGT-1036S

|

840×640×750

|

157

|

2160

|

28/40

|

5000

|

30-110

|

|

VGT-1042S

|

890×690×800

|

206

|

2520

|

28/40

|

6000

|

30-110

|

Details of Sonic Ultrasonic Cleaner:

The solid, sturdy structure and stainless steel SUS304 basket make our Ultrasonic descaler perform perfectly in the business

The whole machine is made of SUS304 stainless steel, 2mm thickness tank for acid-proof, anti-corrosive.

Fully portable, 36L and above volume machines are with wheels, locking wheels for stability.

Application of Ultrasound Cleaning Machine:

Electronics:

An Ultrasonic vibration cleaning machine gets a safe, unwavering cleaning for even the most delicate of components. GT SONIC baths completely remove flux and contaminants from such precision parts as PC boards, SMDs, quartz crystals, capacitors, and many others.

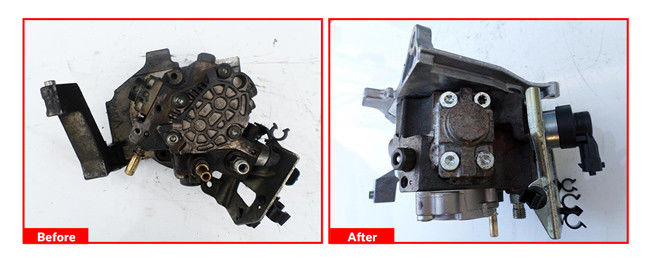

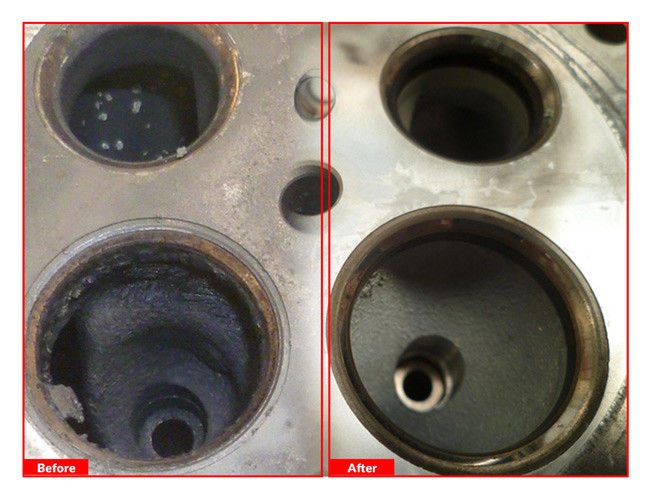

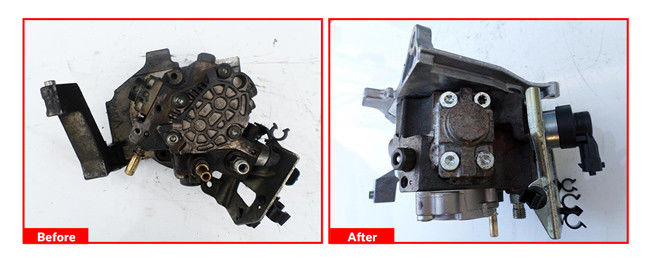

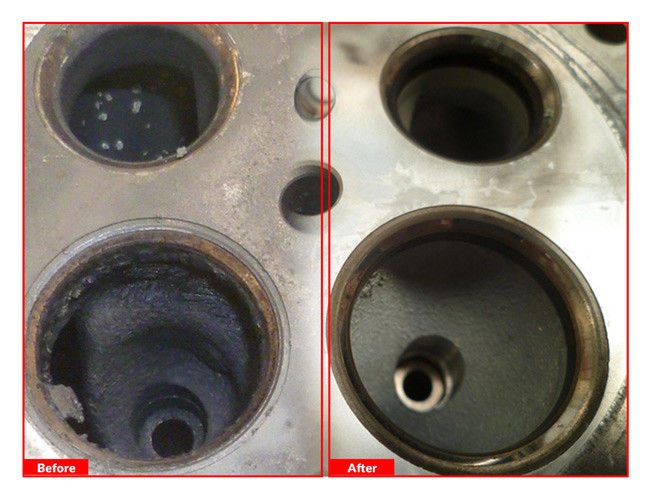

Auto parts:

Ultrasonic technology is changing today’s parts cleaning industry by making precision cleaning safer, faster, less expensive, and more effective. Ultrasonic cleaners offer results far beyond traditional cleaning methods, for everything from carburetors to medical instruments.

Industrial:

The solid, sturdy structure and high-tech design make our Ultrasonic vibration cleaning machine perfect for the business. We manufacture standard systems from one to 206 liters, designed to handle Ultrasonic cleaning parts in a variety of shapes and sizes.

Before-After-Cleaning

FAQ:

1. Which cleaning solution should I use?

A number of detergents, wetting agents, and other such components are used in the making of a modern ultrasonic cleaning solution. And there is a variety of formulations available from which you can take your pick depending on the application. Selecting a proper solution is very important for a satisfactory cleaning job and to stop unwanted reactivity with the part being cleaned.

2. Which cleaning solution shouldn’t I use?

Flammables or solutions that have very low flash points should never be used. Cavitation releases energy which is then turned into heat and kinetic energy. As a result of that, high temperature gradients in the solutions are produced. This can be very hazardous for the part being cleaned. Acids, bleach, and bleach by-products should generally be avoided. but maybe used with indirect cleaning in a proper indirect cleaning container, such as a glass beaker, and appropriate care. Strong acid or alkaline cleaning solution will damage stainless steel tanks, to overcome this problem, pls use a mild PH solution.

3. When should the ultrasonic solutions be changed?

The solution should be changed when the solution is very dirty or depleted or when you notice a decrease in cleaning action. However, you must remember that every cleaning session does not require a new batch of solutions.

4. What are direct and indirect cleaning?

Direct cleaning occurs when the parts are cleaned in the cleaning solution which fills the cleaner. Usual the parts inside the mesh cleaning basket.

Indirect ultrasonic cleaning is used when the parts to be cleaned are placed in a removed tank or beakers that contains cleaning chemical that could damage the ultrasonic cleaner.

5. How to Maintain Your Ultrasonic Cleaners?

In order to function, the ultrasound cleaner needs an adequate solution and by now, you should know to Strong acid or alkaline cleaning solution will cause corrosion, rust, and even puncture of the tank or machine body. To overcome this problem, dilute to mild PH solution or request for a tank made of a specific grade of stainless steel like SUS304.

Always unplug the unit before draining the solution. Leaving the heating elements energized by accident can cause them to overheat and fail. Also, water and electricity don’t mix, and the combination can be lethal when the human body is involved with excess splashing.

DO NOT operate the unit without fluid in the tank. When filling the tank, always ensure that the “MAX” marking is not exceeded.

Do not run the device for an extended time or continuously.

Do not hit the device. Be careful when moving the device.

Use a piece of cloth to clean and dry the tank after using it.

|

| Brand Name: | GT SONIC |

| Model Number: | VGT-1036S |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | standard packing : wooden case |

| Payment Terms: | L/C, T/T |

Ultrasonic Cleaning Machine Features:

1. Whole machine made of SUS304 stainless steel, 2mm thickness tank for acid-proof, anti-corrosive.

2. Industrial grade Ultrasonic transducer, moisture-proofed PCB.

3. Advanced generator, sweep frequency, high quality, better effect.

4. Ultrasonic power can be adjusted from 0-100%.

5. Temperature can be set from 30-110°C.

6. Industrial grade for 24 hours of continuous working.

7. Ultrasonic frequency: 28kHz or 40kHz.

8. Fully portable, 36L and above volume machines are with wheels, locking wheels for stability.

9. With free lid and stainless steel SUS304 basket.

Specifications of Ultrasonic Cleaning Equipment:

|

Model

|

|

Volume

|

Ultrasonic Power

|

Ultrasonic Frequency

|

Heating power

|

Heating temperature

|

|

(L×W×H)mm

|

(L)

|

(W)

|

(kHz)

|

(W)

|

(℃)

|

|

|

VGT-2200QT |

400×360×450

|

13

|

360

|

40

|

500

|

0-80

|

|

VGT-2300

|

570×360×450

|

36

|

720

|

28/40

|

800

|

30-110

|

|

VGT-1012S

|

530×430×600

|

40

|

720

|

28/40

|

2000

|

30-110

|

|

VGT-1018S

|

630×480×650

|

65

|

1080

|

28/40

|

3000

|

30-110

|

|

VGT-1024S

|

730×530×700

|

96

|

1440

|

28/40

|

4000

|

30-110

|

|

VGT-1030S

|

790×590×700

|

117

|

1800

|

28/40

|

4000

|

30-110

|

|

VGT-1036S

|

840×640×750

|

157

|

2160

|

28/40

|

5000

|

30-110

|

|

VGT-1042S

|

890×690×800

|

206

|

2520

|

28/40

|

6000

|

30-110

|

Details of Sonic Ultrasonic Cleaner:

The solid, sturdy structure and stainless steel SUS304 basket make our Ultrasonic descaler perform perfectly in the business

The whole machine is made of SUS304 stainless steel, 2mm thickness tank for acid-proof, anti-corrosive.

Fully portable, 36L and above volume machines are with wheels, locking wheels for stability.

Application of Ultrasound Cleaning Machine:

Electronics:

An Ultrasonic vibration cleaning machine gets a safe, unwavering cleaning for even the most delicate of components. GT SONIC baths completely remove flux and contaminants from such precision parts as PC boards, SMDs, quartz crystals, capacitors, and many others.

Auto parts:

Ultrasonic technology is changing today’s parts cleaning industry by making precision cleaning safer, faster, less expensive, and more effective. Ultrasonic cleaners offer results far beyond traditional cleaning methods, for everything from carburetors to medical instruments.

Industrial:

The solid, sturdy structure and high-tech design make our Ultrasonic vibration cleaning machine perfect for the business. We manufacture standard systems from one to 206 liters, designed to handle Ultrasonic cleaning parts in a variety of shapes and sizes.

Before-After-Cleaning

FAQ:

1. Which cleaning solution should I use?

A number of detergents, wetting agents, and other such components are used in the making of a modern ultrasonic cleaning solution. And there is a variety of formulations available from which you can take your pick depending on the application. Selecting a proper solution is very important for a satisfactory cleaning job and to stop unwanted reactivity with the part being cleaned.

2. Which cleaning solution shouldn’t I use?

Flammables or solutions that have very low flash points should never be used. Cavitation releases energy which is then turned into heat and kinetic energy. As a result of that, high temperature gradients in the solutions are produced. This can be very hazardous for the part being cleaned. Acids, bleach, and bleach by-products should generally be avoided. but maybe used with indirect cleaning in a proper indirect cleaning container, such as a glass beaker, and appropriate care. Strong acid or alkaline cleaning solution will damage stainless steel tanks, to overcome this problem, pls use a mild PH solution.

3. When should the ultrasonic solutions be changed?

The solution should be changed when the solution is very dirty or depleted or when you notice a decrease in cleaning action. However, you must remember that every cleaning session does not require a new batch of solutions.

4. What are direct and indirect cleaning?

Direct cleaning occurs when the parts are cleaned in the cleaning solution which fills the cleaner. Usual the parts inside the mesh cleaning basket.

Indirect ultrasonic cleaning is used when the parts to be cleaned are placed in a removed tank or beakers that contains cleaning chemical that could damage the ultrasonic cleaner.

5. How to Maintain Your Ultrasonic Cleaners?

In order to function, the ultrasound cleaner needs an adequate solution and by now, you should know to Strong acid or alkaline cleaning solution will cause corrosion, rust, and even puncture of the tank or machine body. To overcome this problem, dilute to mild PH solution or request for a tank made of a specific grade of stainless steel like SUS304.

Always unplug the unit before draining the solution. Leaving the heating elements energized by accident can cause them to overheat and fail. Also, water and electricity don’t mix, and the combination can be lethal when the human body is involved with excess splashing.

DO NOT operate the unit without fluid in the tank. When filling the tank, always ensure that the “MAX” marking is not exceeded.

Do not run the device for an extended time or continuously.

Do not hit the device. Be careful when moving the device.

Use a piece of cloth to clean and dry the tank after using it.