| Brand Name: | GT SONIC |

| Model Number: | GT SONIC-ST288A/B |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | Standard packing : PE Foam + Wooden Box |

| Payment Terms: | Western Union, T/T, D/P, D/A, L/C |

28kHz Parts Ultrasonic Cleaner

SUS304 Gun Ultrasonic Cleaner CPB, Heated Soak Tank with Large Capacity 28kHz/40kHz

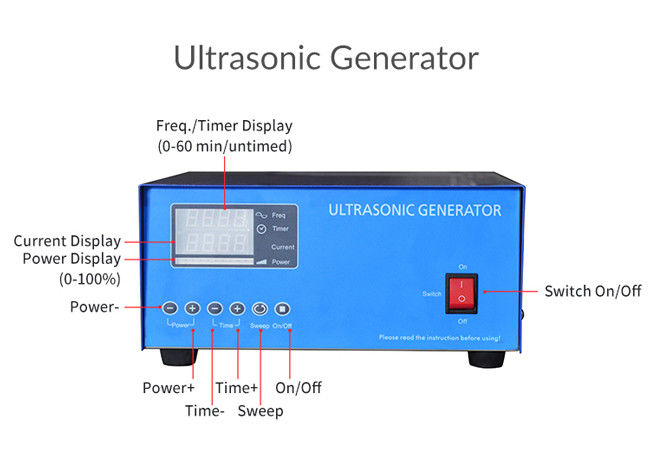

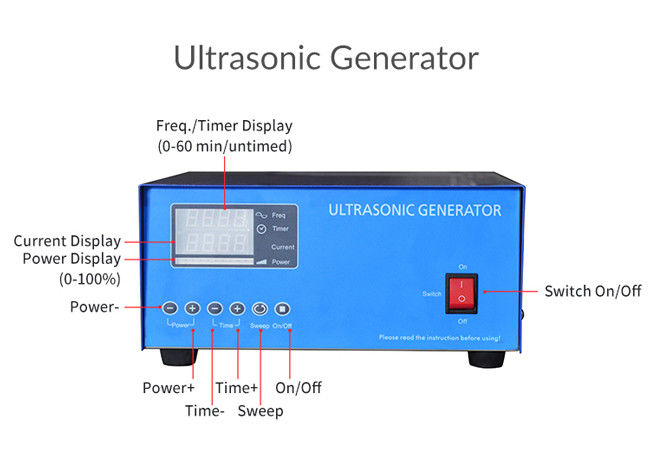

GT SONIC ST-series ultrasonic cleaners with heater, power switch function and sweep function. 28KHz for gross rinse or 40KHz for intensive rinse. Sweep function for optimum sound field distribution and cleaning performance in the entire ultrasonic bath.

General Description of Ultrasonic Parts Washer

GT SONIC manufactures standard industrial ultrasonic cleaning systems from 53 liters to 288 liters. All stainless steel construction and high tech design make the machines with best cleaning effect. We also design and manufacture custom systems for unique applications and can provide components to convert or upgrade an existing tank. Whether you need a system to clean bearings, window blinds, optical precision components or aircraft components, we have an R & D team that can provides you with the results.

Features

1. Ultrasonic power: 0-100% adjustable.

2. Time setting: 0-60min or continues.

3. Heating: 30-100℃.

4. Ultrasonic frequency: 28kHz or 40kHz.

5. Whole machine made of SUS304 stainless steel, 2mm thickness tank for acid-proof, anti-corrosive.

6. Industrial grade ultrasonic transducer, moisture-proofed PCB.

7. Advanced generator, sweep frequency, high quality, better effect.

8. Fully portable, 36L and above volume machines are with wheels, locking wheels for stability.

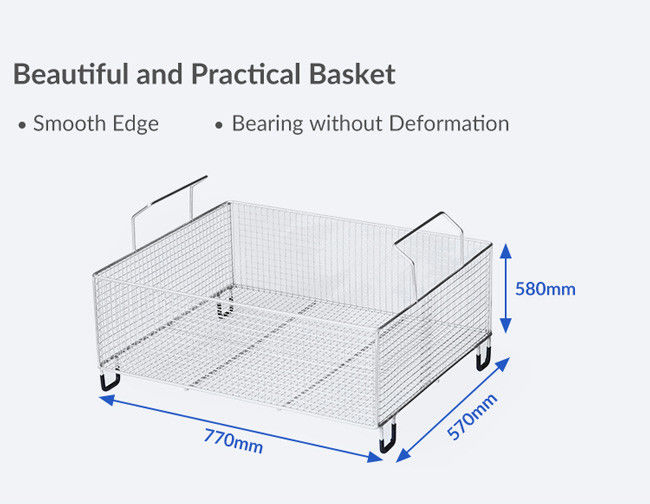

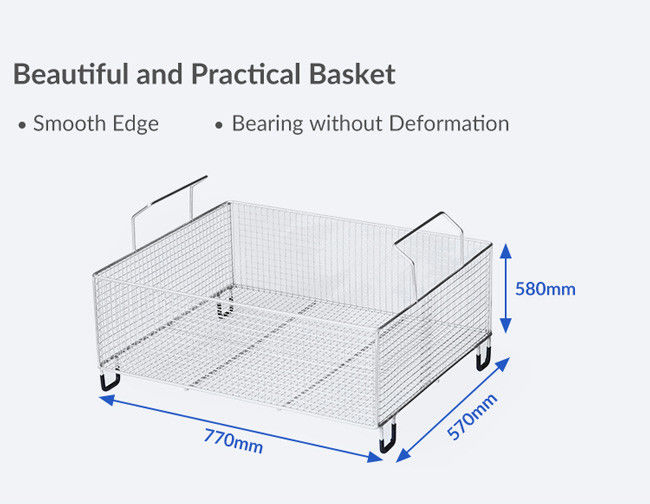

9. With free lid and stainless steel SUS304 basket.

10. Customized according to customer's request.

Applications

The ultra sound cleans everywhere the cleaning liquid is able to reach and thus even gets to interior places which are very hard to reach. Follow some samples that you can clean:

Aircraft components, brakes, machined parts

Anything that is honed, lapped, buffed, or polished (ceramic, glass, metals) Automotive fuel injector nozzles and components

Bearings

Blind cleaning (window blinds) Carbide cutting tools

Cathode ray tube components (TV picture tube components) Computer disk drive and head components

Fire restoration Glass substrates

Glassware cleaning (laboratory glassware)

Hybrid microelectronic circuits (thin and thick film circuits) Hypodermic needle stock (cannulae)

Jewelry cleaning (new manufacture) Lenses, ophthalmic, precision

Maintenance - cleaning of electronic assemblies Maintenance - cleaning mechanical assemblies

Maintenance - cleaning of food manufacturing filling equipment Medical glassware (vials)

Molds (maintenance cleaning) Nuclear decontamination Optical components Orthopedic implants

Preparation of metals prior to titanium nitride coating

Quartz crystals (radio, television, computer, pagers, cellular phones) Semiconductor, components, substrates, and sub-assemblies) Surgical instruments

Thick film furnace belt (during operation) Weapons (maintenance cleaning)

Wire dies (drawing dies)

Specification:

|

Model |

Tank Size LxWxH(mm) |

Unit Size LxWxH(mm) |

Volume (L) |

Ultrasonic Power (W) |

Ultrasonic Frequency (KHz) |

Heating Power (W) |

Timer (min) |

Temp. (°C) |

|

ST53A/B |

500*350*300 |

645*496*615 |

53 |

900 |

28/40kHz |

2000 |

0-60 minutes /untimed |

30-110(℃) |

|

ST77A/B |

550*400*350 |

687*540*610 |

77 |

1200 |

3000 |

|||

|

ST105A/B |

600*500*350 |

745*645*665 |

105 |

1500 |

4000 |

|||

|

ST144A/B |

600*600*400 |

745*745*715 |

144 |

1800 |

5000 |

|||

|

ST189A/B |

700*600*450 |

845*745*765 |

189 |

2400 |

6000 |

|||

|

ST288A/B |

800*600*600 |

942*745*915 |

288 |

3000 |

7000 |

Product Details:

| Brand Name: | GT SONIC |

| Model Number: | GT SONIC-ST288A/B |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | Standard packing : PE Foam + Wooden Box |

| Payment Terms: | Western Union, T/T, D/P, D/A, L/C |

28kHz Parts Ultrasonic Cleaner

SUS304 Gun Ultrasonic Cleaner CPB, Heated Soak Tank with Large Capacity 28kHz/40kHz

GT SONIC ST-series ultrasonic cleaners with heater, power switch function and sweep function. 28KHz for gross rinse or 40KHz for intensive rinse. Sweep function for optimum sound field distribution and cleaning performance in the entire ultrasonic bath.

General Description of Ultrasonic Parts Washer

GT SONIC manufactures standard industrial ultrasonic cleaning systems from 53 liters to 288 liters. All stainless steel construction and high tech design make the machines with best cleaning effect. We also design and manufacture custom systems for unique applications and can provide components to convert or upgrade an existing tank. Whether you need a system to clean bearings, window blinds, optical precision components or aircraft components, we have an R & D team that can provides you with the results.

Features

1. Ultrasonic power: 0-100% adjustable.

2. Time setting: 0-60min or continues.

3. Heating: 30-100℃.

4. Ultrasonic frequency: 28kHz or 40kHz.

5. Whole machine made of SUS304 stainless steel, 2mm thickness tank for acid-proof, anti-corrosive.

6. Industrial grade ultrasonic transducer, moisture-proofed PCB.

7. Advanced generator, sweep frequency, high quality, better effect.

8. Fully portable, 36L and above volume machines are with wheels, locking wheels for stability.

9. With free lid and stainless steel SUS304 basket.

10. Customized according to customer's request.

Applications

The ultra sound cleans everywhere the cleaning liquid is able to reach and thus even gets to interior places which are very hard to reach. Follow some samples that you can clean:

Aircraft components, brakes, machined parts

Anything that is honed, lapped, buffed, or polished (ceramic, glass, metals) Automotive fuel injector nozzles and components

Bearings

Blind cleaning (window blinds) Carbide cutting tools

Cathode ray tube components (TV picture tube components) Computer disk drive and head components

Fire restoration Glass substrates

Glassware cleaning (laboratory glassware)

Hybrid microelectronic circuits (thin and thick film circuits) Hypodermic needle stock (cannulae)

Jewelry cleaning (new manufacture) Lenses, ophthalmic, precision

Maintenance - cleaning of electronic assemblies Maintenance - cleaning mechanical assemblies

Maintenance - cleaning of food manufacturing filling equipment Medical glassware (vials)

Molds (maintenance cleaning) Nuclear decontamination Optical components Orthopedic implants

Preparation of metals prior to titanium nitride coating

Quartz crystals (radio, television, computer, pagers, cellular phones) Semiconductor, components, substrates, and sub-assemblies) Surgical instruments

Thick film furnace belt (during operation) Weapons (maintenance cleaning)

Wire dies (drawing dies)

Specification:

|

Model |

Tank Size LxWxH(mm) |

Unit Size LxWxH(mm) |

Volume (L) |

Ultrasonic Power (W) |

Ultrasonic Frequency (KHz) |

Heating Power (W) |

Timer (min) |

Temp. (°C) |

|

ST53A/B |

500*350*300 |

645*496*615 |

53 |

900 |

28/40kHz |

2000 |

0-60 minutes /untimed |

30-110(℃) |

|

ST77A/B |

550*400*350 |

687*540*610 |

77 |

1200 |

3000 |

|||

|

ST105A/B |

600*500*350 |

745*645*665 |

105 |

1500 |

4000 |

|||

|

ST144A/B |

600*600*400 |

745*745*715 |

144 |

1800 |

5000 |

|||

|

ST189A/B |

700*600*450 |

845*745*765 |

189 |

2400 |

6000 |

|||

|

ST288A/B |

800*600*600 |

942*745*915 |

288 |

3000 |

7000 |

Product Details: