| Brand Name: | GT SONIC |

| Model Number: | GT SONIC-D27 |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | Carton packing |

| Payment Terms: | L/C, T/T |

Ultrasonic energy is far superior to manually scrub these instruments because the microscopic bubbles are able to penetrate small cracks and crevices to blast away contaminants unreachable by manual processes. Moreover, the chances of personnel receiving cuts or puncture wounds are greatly reduced.

Cleaning procedures should follow the recommendations of professional associations along with those of Ultrasonic equipment and suppliers of cleaning solutions formulated for medical and surgical instruments.

| Model | Tank Size | Unit Size | Volume | Ultrasonic Power | Ultrasonic Frequency | Heating Power | Timer | Heating Tem. |

| LxWxH(mm) | LxWxH(mm) | (L) | (W) | (KHz) | (W) | (min) | (°C) | |

| GT SONIC-D2 | 150*140*100 | 190*170*220 | 2 | 50 | 40 | 100 | 1-99 | 0-80 |

| GT SONIC-D3 | 240*140*100 | 270*170*240 | 3 | 100 | 100 | |||

| GT SONIC-D6 | 300*155*150 | 330*180*310 | 6 | 150 | 300 | |||

| GT SONIC-D9 | 300*240*150 | 330*270*310 | 9 | 200 | 300 | |||

| GT SONIC-D13 | 330*300*150 | 360*330*310 | 13 | 300 | 400 | |||

| GT SONIC-D20 | 500*300*150 | 550*330*310 | 20 | 400 | 500 | |||

| GT SONIC-D27 | 500*300*200 | 550*330*360 | 27 | 500 | 500 |

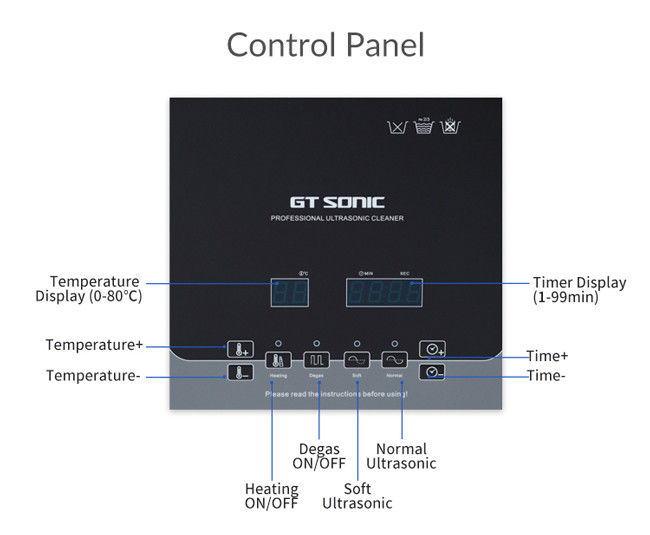

1. Normal and soft power control to resolve the cleaning blind spot.

2. Degas function for improving the cleaning effect.

3. Time Setting:1-99minutes adjustable.

4. Heating: 0-80℃ temperature adjustable

5. User-friendly and clear panel

6. Memory function

7. LED display for temperature and timer

8. High-performance transducer

9. Patent products

Application for Cleaning Printed Circuit Boards

Contaminants such as excess solder and rosins must be removed from newly manufactured printed circuit boards. Ultrasonic cleaners effectively accomplish this when proven procedures are employed.

FAQ:

Which cleaning solution shouldn’t I use?

Flammables or solutions that have very low flash points should never be used. Cavitation releases energy which is then turned into heat and kinetic energy. As a result of that, high-temperature gradients in the solutions are produced. This can be very hazardous for the part being cleaned. Acids, bleach and bleach by-products should generally be avoided. but maybe used with indirect cleaning in a proper indirect cleaning container, such as a glass beaker, and appropriate care. A strong acid or alkaline cleaning solution will damage stainless steel tanks, to overcome this problem, pls use a mild PH solution.

More than ten years of manufacturing experience in the ultrasound field

ISO 9001, ISO 14001, rated as National High-tech Enterprise

Became a listed company in 2015

40,000 square meters of the industrial park

Domestic top R&D center leading by 6 national experts who have over ten years experience in the Ultrasonic field, and 40 senior engineers

Obtain more than 70 patents by the end of 2017

Completed countless ODM projects for many world-class companies

7 days of leading time for standard models, 25 days of leading time for custom products

Experienced oversea sales team to offer market advice and order guidance.

Provide prompt and effective after-sales service and support

Professional technicals to help you solve your Ultrasonic cleaning difficulties

| Brand Name: | GT SONIC |

| Model Number: | GT SONIC-D27 |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | Carton packing |

| Payment Terms: | L/C, T/T |

Ultrasonic energy is far superior to manually scrub these instruments because the microscopic bubbles are able to penetrate small cracks and crevices to blast away contaminants unreachable by manual processes. Moreover, the chances of personnel receiving cuts or puncture wounds are greatly reduced.

Cleaning procedures should follow the recommendations of professional associations along with those of Ultrasonic equipment and suppliers of cleaning solutions formulated for medical and surgical instruments.

| Model | Tank Size | Unit Size | Volume | Ultrasonic Power | Ultrasonic Frequency | Heating Power | Timer | Heating Tem. |

| LxWxH(mm) | LxWxH(mm) | (L) | (W) | (KHz) | (W) | (min) | (°C) | |

| GT SONIC-D2 | 150*140*100 | 190*170*220 | 2 | 50 | 40 | 100 | 1-99 | 0-80 |

| GT SONIC-D3 | 240*140*100 | 270*170*240 | 3 | 100 | 100 | |||

| GT SONIC-D6 | 300*155*150 | 330*180*310 | 6 | 150 | 300 | |||

| GT SONIC-D9 | 300*240*150 | 330*270*310 | 9 | 200 | 300 | |||

| GT SONIC-D13 | 330*300*150 | 360*330*310 | 13 | 300 | 400 | |||

| GT SONIC-D20 | 500*300*150 | 550*330*310 | 20 | 400 | 500 | |||

| GT SONIC-D27 | 500*300*200 | 550*330*360 | 27 | 500 | 500 |

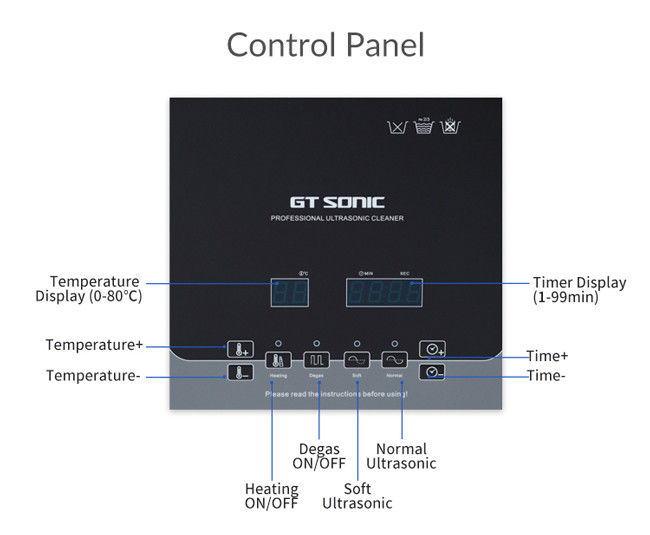

1. Normal and soft power control to resolve the cleaning blind spot.

2. Degas function for improving the cleaning effect.

3. Time Setting:1-99minutes adjustable.

4. Heating: 0-80℃ temperature adjustable

5. User-friendly and clear panel

6. Memory function

7. LED display for temperature and timer

8. High-performance transducer

9. Patent products

Application for Cleaning Printed Circuit Boards

Contaminants such as excess solder and rosins must be removed from newly manufactured printed circuit boards. Ultrasonic cleaners effectively accomplish this when proven procedures are employed.

FAQ:

Which cleaning solution shouldn’t I use?

Flammables or solutions that have very low flash points should never be used. Cavitation releases energy which is then turned into heat and kinetic energy. As a result of that, high-temperature gradients in the solutions are produced. This can be very hazardous for the part being cleaned. Acids, bleach and bleach by-products should generally be avoided. but maybe used with indirect cleaning in a proper indirect cleaning container, such as a glass beaker, and appropriate care. A strong acid or alkaline cleaning solution will damage stainless steel tanks, to overcome this problem, pls use a mild PH solution.

More than ten years of manufacturing experience in the ultrasound field

ISO 9001, ISO 14001, rated as National High-tech Enterprise

Became a listed company in 2015

40,000 square meters of the industrial park

Domestic top R&D center leading by 6 national experts who have over ten years experience in the Ultrasonic field, and 40 senior engineers

Obtain more than 70 patents by the end of 2017

Completed countless ODM projects for many world-class companies

7 days of leading time for standard models, 25 days of leading time for custom products

Experienced oversea sales team to offer market advice and order guidance.

Provide prompt and effective after-sales service and support

Professional technicals to help you solve your Ultrasonic cleaning difficulties