| Brand Name: | GT SONIC |

| Model Number: | GT SONIC-D27 |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | standard packing : PE Foam + carton packing |

| Payment Terms: | L/C, T/T |

40kHz Digital Ultrasonic Cleaner

Printing Nozzle Digital Ultrasonic Cleaner Stainless Steel Tank Standard Basket

27L 3D Printing Nozzle Cleaning Digital Ultrasonic Cleaner GT SONIC-D27

Ultrasonic Instrument Cleaner Specification:

Model | Tank Size | Unit Size | Volume | Ultrasonic Power | Ultrasonic Frequency | Heating Power | Timer | Heating Tem. |

LxWxH(mm) | LxWxH(mm) | (L) | (W) | (KHz) | (W) | (min) | (°C) | |

GT SONIC-D2 | 150*140*100 | 190*170*220 | 2 | 50 | 40 | 100 | 1-99 | 0-80 |

GT SONIC-D3 | 240*140*100 | 270*170*240 | 3 | 100 | 100 | |||

GT SONIC-D6 | 300*155*150 | 330*180*310 | 6 | 150 | 300 | |||

GT SONIC-D9 | 300*240*150 | 330*270*310 | 9 | 200 | 300 | |||

GT SONIC-D13 | 330*300*150 | 360*330*310 | 13 | 300 | 400 | |||

GT SONIC-D20 | 500*300*150 | 550*330*310 | 20 | 400 | 500 | |||

GT SONIC-D27 | 500*300*200 | 550*330*360 | 27 | 500 | 500 |

Features of Digital Ultrasonic Cleaner:

* Standard basket and lid.

* Fully microprocessor controller and programmable.

* Digital display, easy operation for time and temperature setting.

* Count-down time and actual temperature real time displaying.

* Power Supply: AC220v±10%

Digital Ultrasonic Cleaner Application:

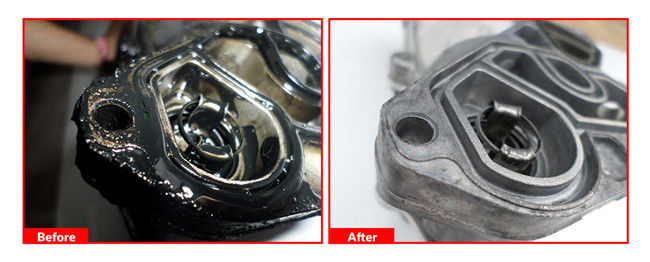

The design of the equipment is based on the users' requirement of Ultrasonic power, Ultrasonic frequency, Ultrasonic time. having the following functions: cleaning, decentralized extraction, no-preparation, chemical reactions, degassing, defoaming, emulsification, mixing etc, the whole process of perfunctory washing, washing in clean water, precision cleaning and rinse is completed within a single machine, giving a thorough cleaning to the washing objects with the result that no fine and stubborn dirt is left anywhere.

To keep the quality of Ultrasonic cleaners ,what we did ?

Raw Material Inspection:

Most of our raw material suppliers are located in GT SONIC technology park ,our QC and engineers would make strict inspection of the raw material step by step to ensure quality product.Any unqualified material will be rejected to guarantee best quality .

100% product inspection:

We QC team would check the production process to ensure machine 100% qualified. Each unit would be under testing at least 4hours before packed ,and sales person will send inspection pictures for your checking .

| Brand Name: | GT SONIC |

| Model Number: | GT SONIC-D27 |

| MOQ: | 1 pc |

| Price: | Negotiable |

| Packaging Details: | standard packing : PE Foam + carton packing |

| Payment Terms: | L/C, T/T |

40kHz Digital Ultrasonic Cleaner

Printing Nozzle Digital Ultrasonic Cleaner Stainless Steel Tank Standard Basket

27L 3D Printing Nozzle Cleaning Digital Ultrasonic Cleaner GT SONIC-D27

Ultrasonic Instrument Cleaner Specification:

Model | Tank Size | Unit Size | Volume | Ultrasonic Power | Ultrasonic Frequency | Heating Power | Timer | Heating Tem. |

LxWxH(mm) | LxWxH(mm) | (L) | (W) | (KHz) | (W) | (min) | (°C) | |

GT SONIC-D2 | 150*140*100 | 190*170*220 | 2 | 50 | 40 | 100 | 1-99 | 0-80 |

GT SONIC-D3 | 240*140*100 | 270*170*240 | 3 | 100 | 100 | |||

GT SONIC-D6 | 300*155*150 | 330*180*310 | 6 | 150 | 300 | |||

GT SONIC-D9 | 300*240*150 | 330*270*310 | 9 | 200 | 300 | |||

GT SONIC-D13 | 330*300*150 | 360*330*310 | 13 | 300 | 400 | |||

GT SONIC-D20 | 500*300*150 | 550*330*310 | 20 | 400 | 500 | |||

GT SONIC-D27 | 500*300*200 | 550*330*360 | 27 | 500 | 500 |

Features of Digital Ultrasonic Cleaner:

* Standard basket and lid.

* Fully microprocessor controller and programmable.

* Digital display, easy operation for time and temperature setting.

* Count-down time and actual temperature real time displaying.

* Power Supply: AC220v±10%

Digital Ultrasonic Cleaner Application:

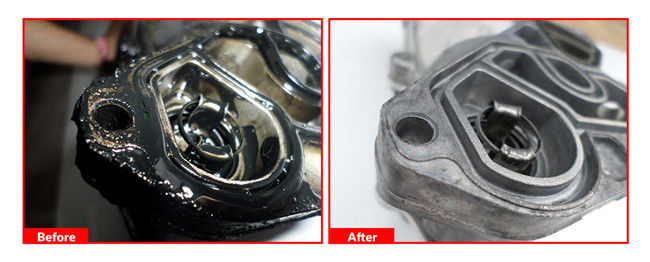

The design of the equipment is based on the users' requirement of Ultrasonic power, Ultrasonic frequency, Ultrasonic time. having the following functions: cleaning, decentralized extraction, no-preparation, chemical reactions, degassing, defoaming, emulsification, mixing etc, the whole process of perfunctory washing, washing in clean water, precision cleaning and rinse is completed within a single machine, giving a thorough cleaning to the washing objects with the result that no fine and stubborn dirt is left anywhere.

To keep the quality of Ultrasonic cleaners ,what we did ?

Raw Material Inspection:

Most of our raw material suppliers are located in GT SONIC technology park ,our QC and engineers would make strict inspection of the raw material step by step to ensure quality product.Any unqualified material will be rejected to guarantee best quality .

100% product inspection:

We QC team would check the production process to ensure machine 100% qualified. Each unit would be under testing at least 4hours before packed ,and sales person will send inspection pictures for your checking .